Wood processing technology

100% Finnish partner for the wood processing industry

We are a project/custom machine shop that designs, manufactures, installs and modernizes production equipment for sawmills, plywood factories and heating plants. Our expertise lies in tailor-made solutions that we implement in close cooperation with our customers – the goal is always to increase production efficiency and achieve the best possible end result.

We supply a wide range of conveyor systems, such as:

- Belt conveyors

- Apron/steelbelt conveyors

- Screw conveyors

- Stair dispensers

- Bark/collar conveyors

- Maintenance/access platforms

- Warehouse storage walls

- Line systems/modernizations

In addition, we offer sawnwood elevators and conveyor tracks that are designed especially for the needs of the wood processing industry.

The most important thing for us is a customer-specific, functional and sustainable overall solution – with Finnish quality and professionalism.

A few of the product solutions we have implemented are presented below:

Belt Conveyor Apron/steelbelt conveyors Stair dispensers Bark/collar conveyors Maintenance/access platforms Warehouse storage walls Line systems/modernizations

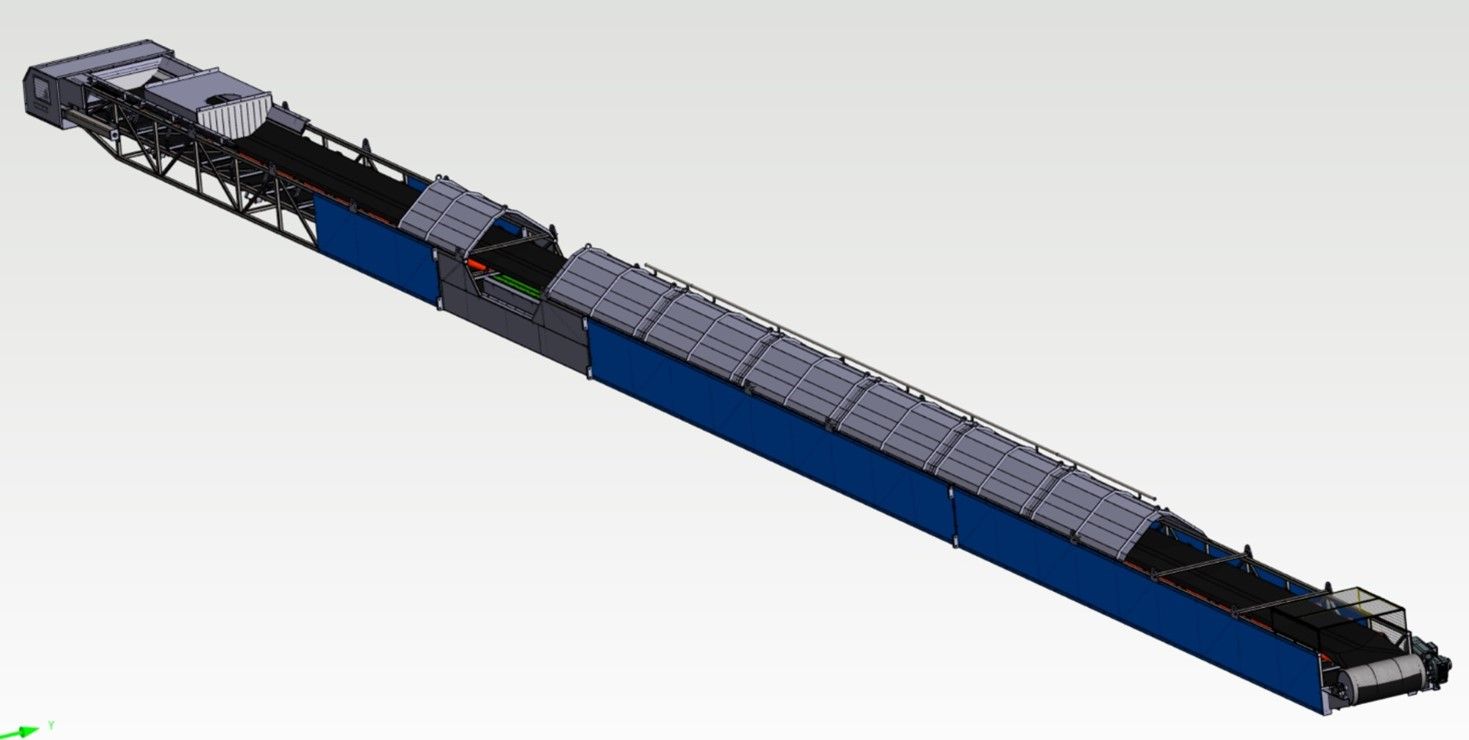

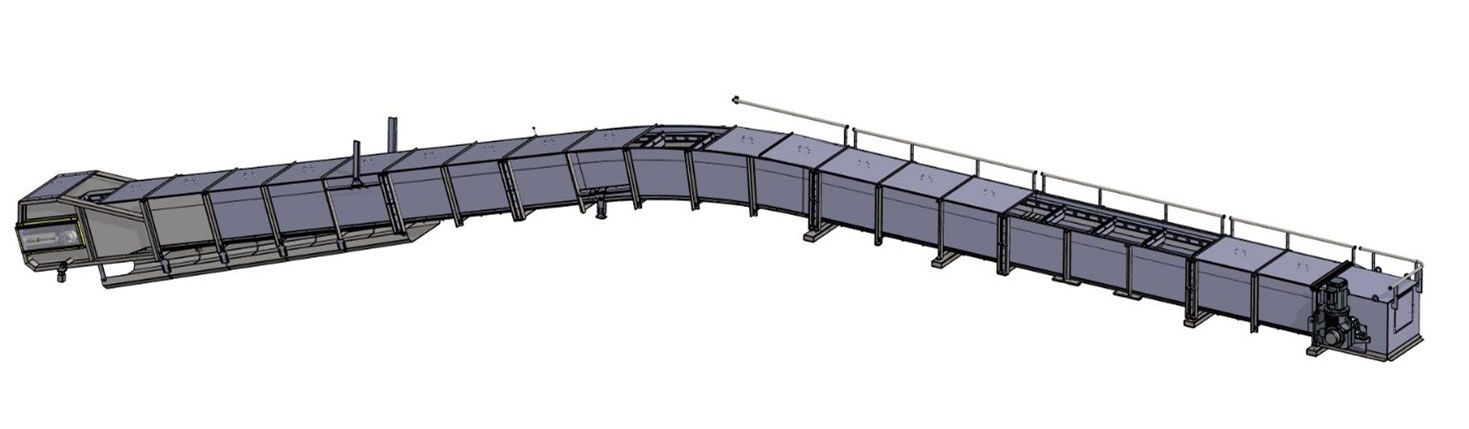

Belt Conveyor

RecTec belt conveyors are reliable, durable and safe. Depending on the material to be transported on the line, either a roller gantry, sliding side or sliding floor conveyor is selected. The cleaning equipment, dust protection and protections required by law, which are important for the operation, are arranged according to the requirements of the process and the installation site.

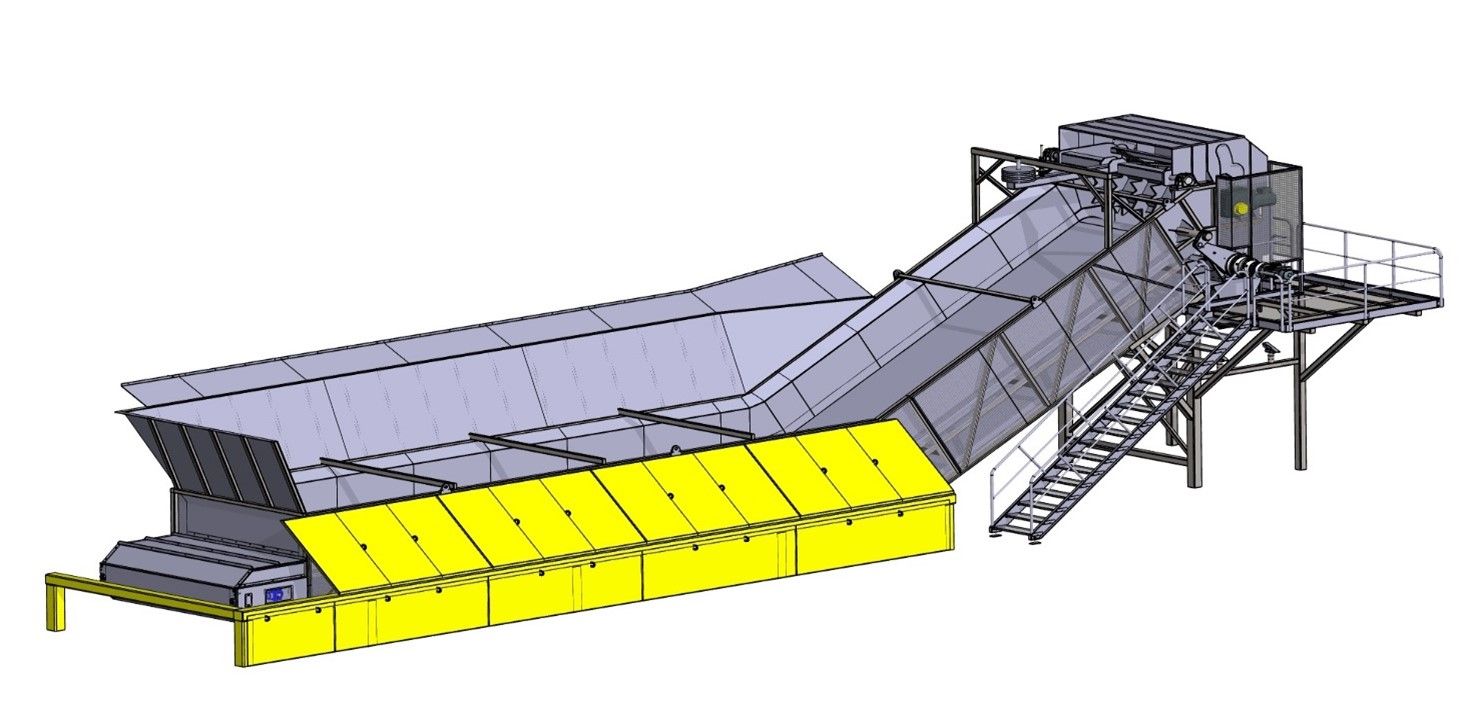

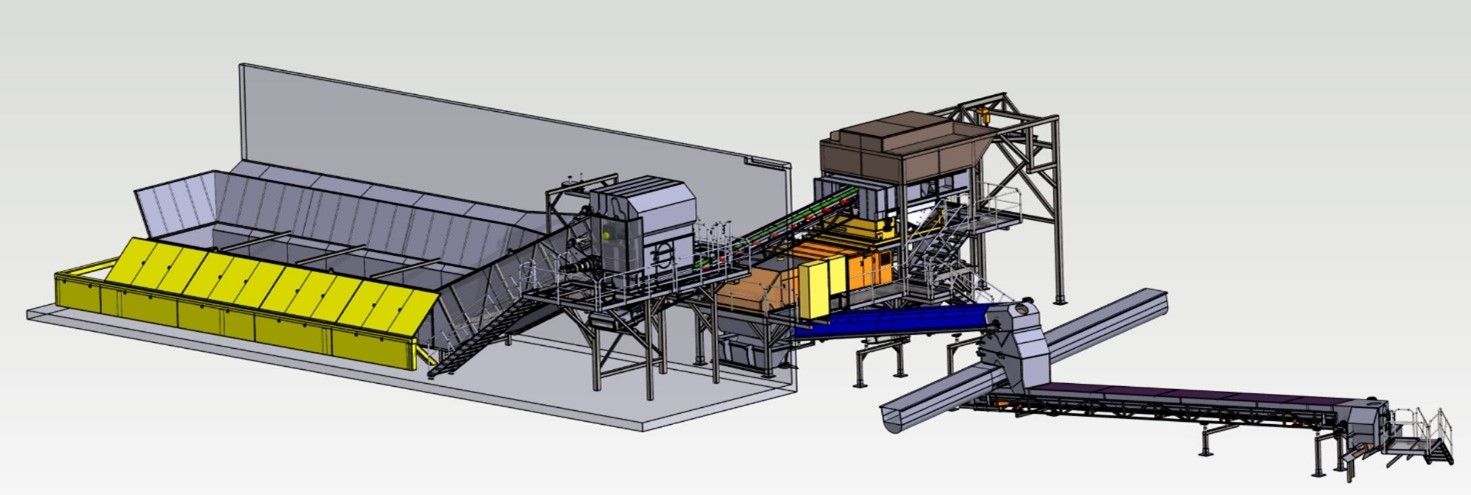

Apron/Steelbelt Conveyors

RecTec's steelbelt conveyor is made for extremely hard use. A steelbelt conveyor can be used to combine a large storage space with a reliable and well-adjustable line feed.

Precise adjustability is obtained with a planetary gearbox or hydraulic motor. Thanks to the rubber-sealed lamellas, the fine material does not cause wear on the equipment and does not interfere with production.

The width of the feeding device can be from one meter to three meters and the length from 3 to 50 meters. In addition to the horizontal section, the conveyor can have a rising section of up to 35 degrees, thanks to which the material can be fed smoothly into the process. The conveyor can be equipped with a feed roller to ensure a smooth feed. As a chain structure, the conveyor is durable, quiet, energy-efficient and has only a few wearing parts.

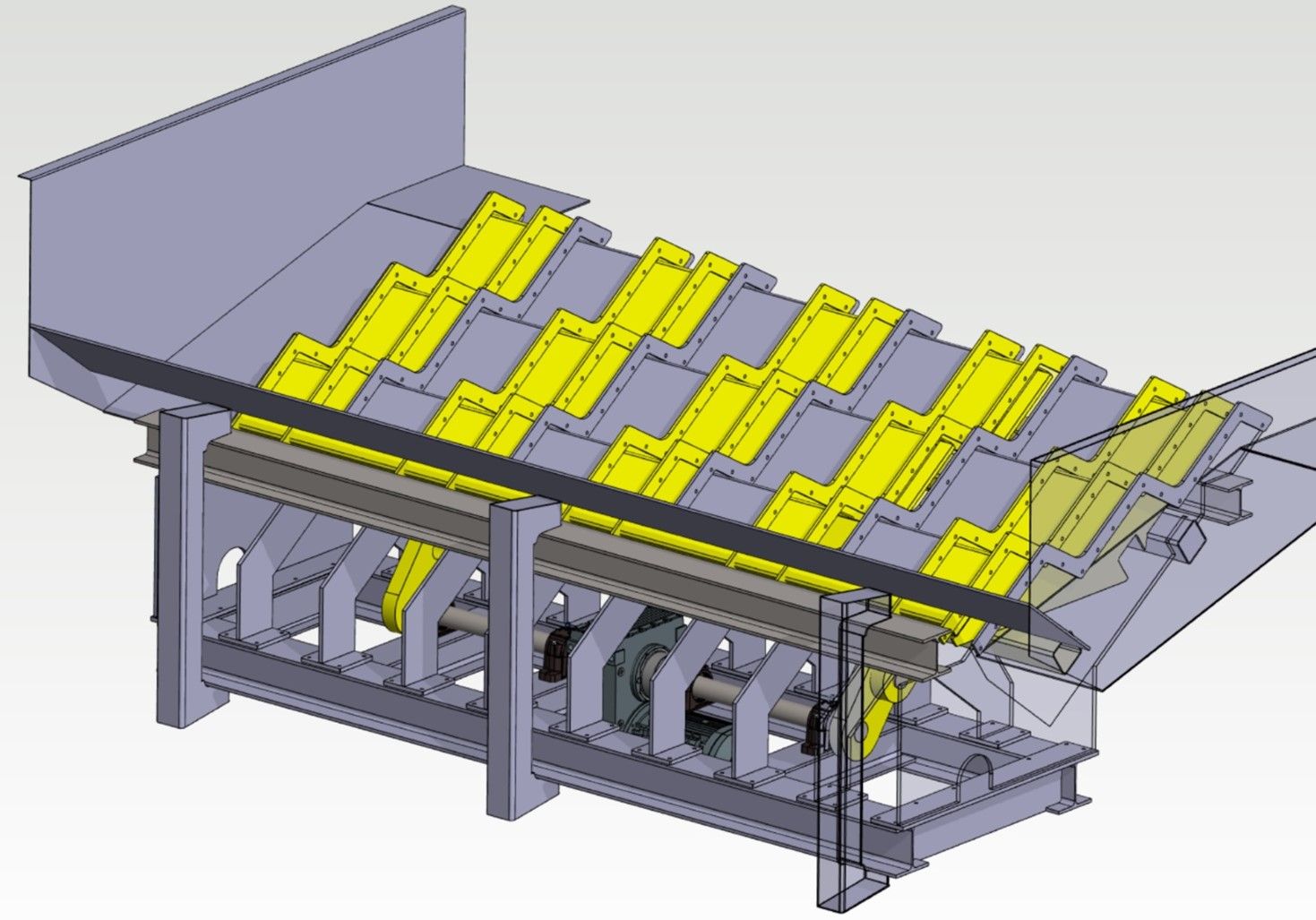

Stair Dispenser

The RecTec log stair dispenser is designed for small and large logs (min 150mm - max 600mm). The log stair dispenser is designed with a durable and reliable mechanical crank mechanism, which ensures smooth and effortless operation and keeps production running smoothly.

Bark/Collar Conveyor

The RecTec Bark/collar conveyor is particularly suitable for the needs of the forest industry and recycling industries, where the transfer of bark and other light materials is an essential part of the production process.

Maintenance and Access Platforms

We design and manufacture maintenance and access platforms for customer premises and around machines and equipment. The platforms are designed in accordance with standards and comply with occupational safety regulations. The platforms are prefabricated in our factory, which keeps the installation time as short as possible.

Warehouse Storage Walls

Our storage walls are suitable for both outdoor and indoor use. They take up less space than concrete walls and it is easy to build a canopy on top of them or install conveyors that drop the material directly into the right pallet.

The walls are durable, easy to modify and quick to install. Ideal for storing sawdust, wood chips and pellets.

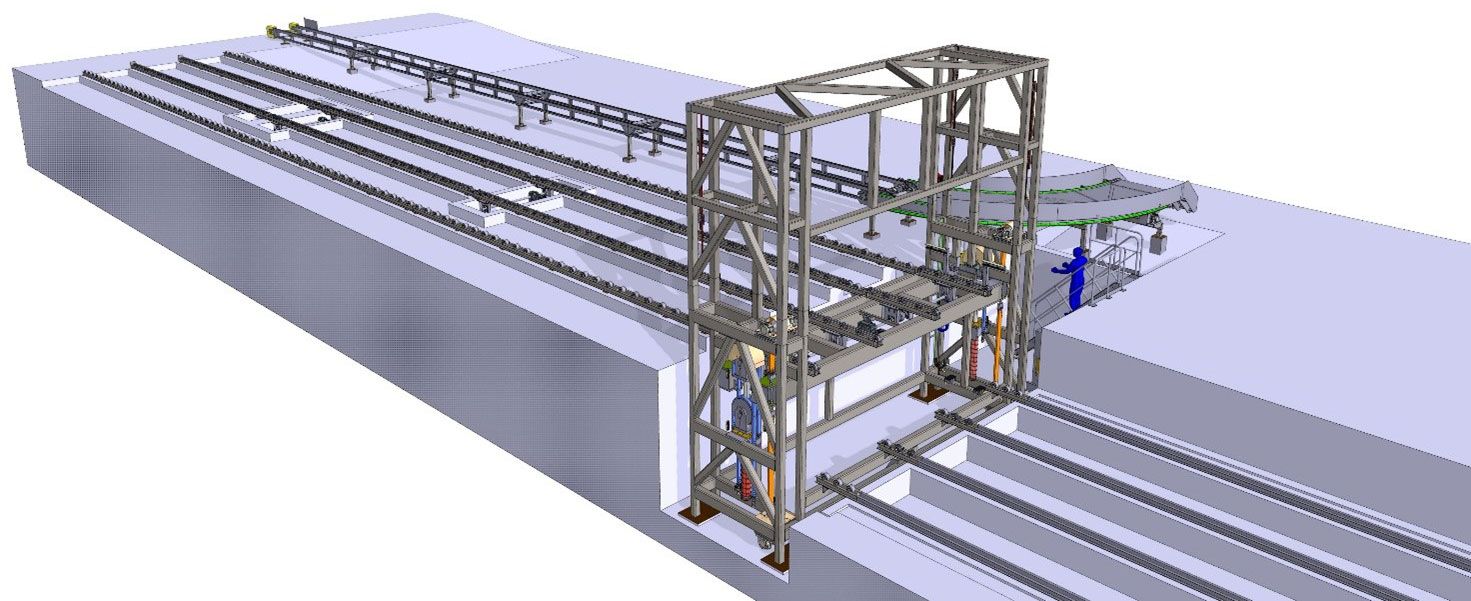

Line Systems and Modernizations

RecTec does not just supply machines and equipment, but offers its customers comprehensive solutions. The company's machines and equipment are only one part of a larger whole. The real added value comes from the careful design, manufacture and installation of the production lines.

RecTec's expertise covers the implementation of new lines as well as the modernization of old facilities. This ensures that the customer's production operates efficiently, reliably and with modern equipment.